CAMLogic excited to announce the launch of our new manufacturing line dedicated to vibrating level switches! This advancement enhances our production capabilities, ensuring higher efficiency, precision, and quality for our customers.

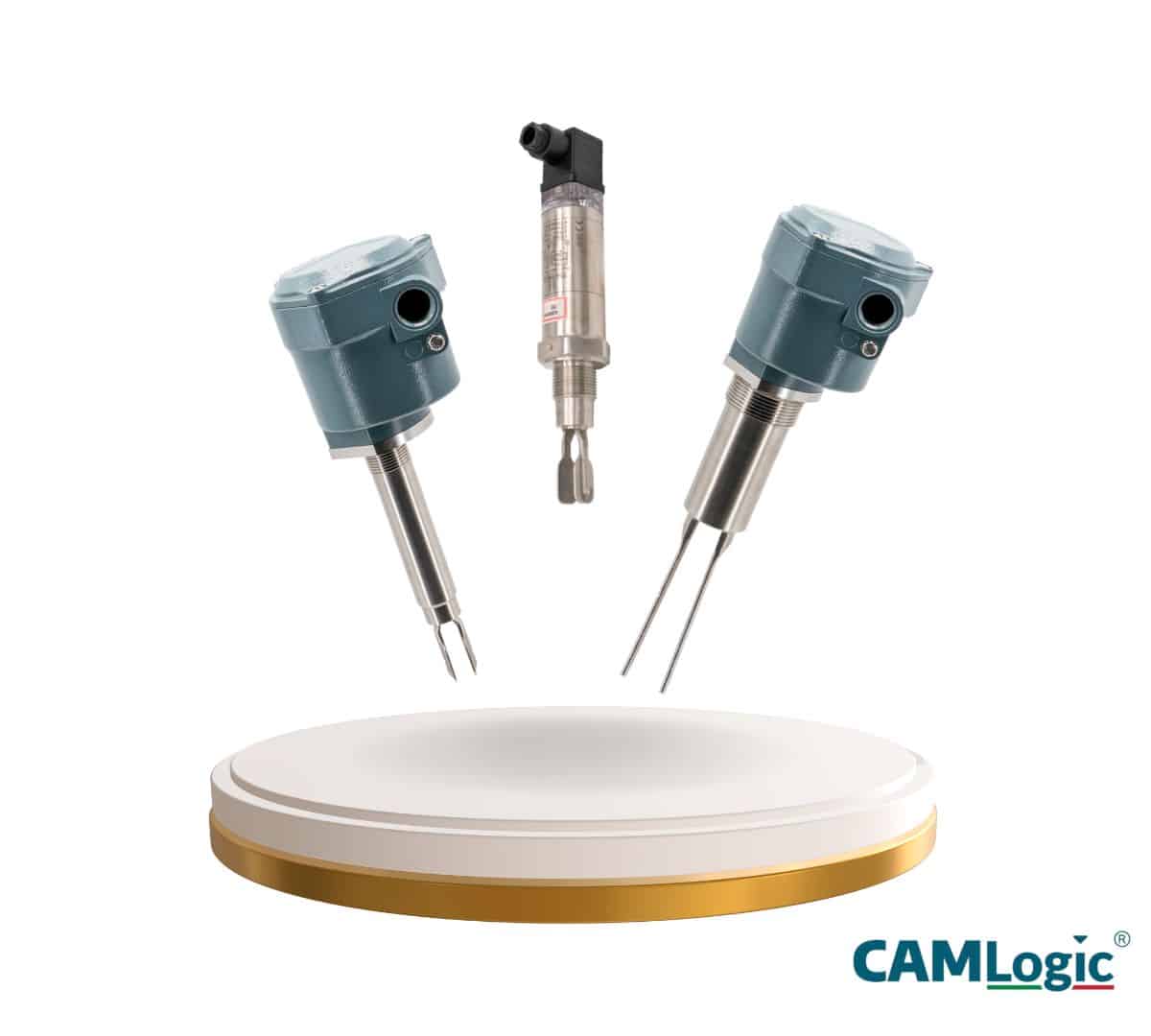

When it comes to level detection, accuracy and reliability are essential. Vibrating technology offers a proven, high-performance solution that industries can depend on. That’s why CAMLogic is proud to introduce three new budget-friendly vibrating level switches, each designed to meet the specific needs of different sectors, delivering unmatched performance and adaptability.

Each of these Level switches is built on the same vibrating fork technology, ensuring precise level detection, zero maintenance, and easy installation. Whether you’re working with liquids, powders, or bulk solids, there’s a perfect Camlogic level switch for your needs.

Why Vibrating Fork Technology?

Vibrating fork technology offers a robust, maintenance-free, and highly accurate solution for level detection. Their reliability in harsh conditions and immunity to material variations make them an excellent choice for industries that demand precision and safety.

All three models—GVS25, GVL30, and GVL1C—use a piezoelectric-driven tuning fork that vibrates at a specific frequency. When the fork comes into contact with a material (liquid or solid), the vibration dampens, triggering a signal to indicate the presence or absence of the material.

Key benefits of vibrating fork technology:

No moving parts: no wear and tear, meaning longer life.

No calibration required: immediately ready to use.

Works in tough conditions: handles pressure, temperature, and dust.

Versatile Application: suitable for hoppers, silos, tanks, and pipelines.

Cost-Effective: budget-friendly, long life.